At present, the main mold production bases in China are in Guangdong, Zhejiang, Jiangsu, Shanghai and Anhui.

In recent years, the structure of my country’s mold industry, whether it is enterprise organizational structure, product structure, technical structure and import and export structure, is developing in the direction of rationalization. In order to update and improve the equipment level, mold enterprises need to import equipment worth billions of yuan every year. Industry insiders believe that the investment in innovation and development is still insufficient, and the improvement of comprehensive R&D capabilities in the mold industry needs to be improved in the following aspects:

1) Improvement of innovation ability;

2) Overall efficiency is improved;

3) The degree of specialization, standardization, commercialization, and collaboration need to be improved;

4) Mold materials and mold-related technologies should be strengthened;

5) The organizational structure, product structure, technical structure and import and export structure of the enterprise are reasonable;

6) Compared with the international advanced level, the management and technology of mold enterprises need to improve.

5, the development trend of China’s mold industry

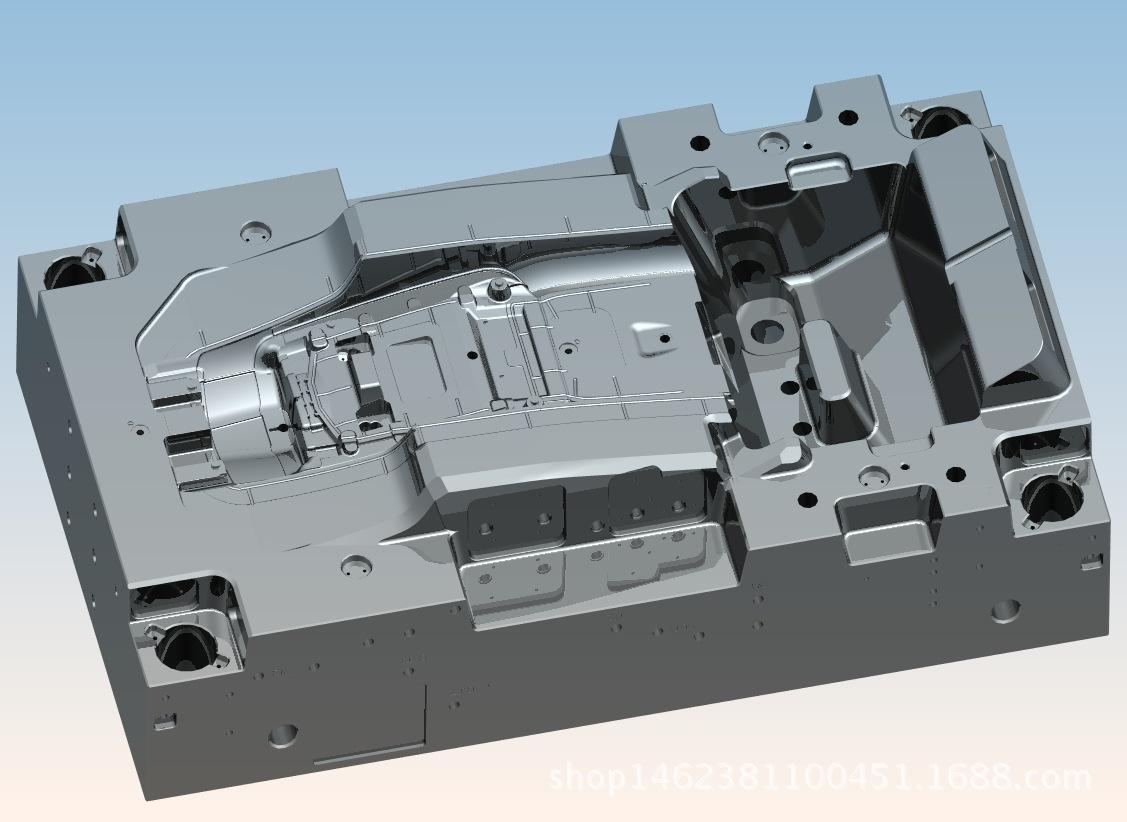

In the next ten years, the development trend of China’s mold industry is: mold products are developing in the direction of large-scale, precise, complex, economical and fast; the technical content of molds is constantly improving, and the mold manufacturing cycle is continuously shortened; mold production is moving towards informationization and no drawing. The direction of development, refinement and automation; mold enterprises are developing in the direction of technology integration, sophisticated equipment, product branding, management informatization, and internationalization of operations. The development of mold technology focuses on the following aspects.

1) The mold structure is becoming larger, more precise, more complex, and the service life is increasing;

2) The wide application of CAD/CAE/CAM technology in mold design and manufacture;

3) Promotion and application of new technologies in mold design and manufacture;

4) The level of mold standardization and the utilization rate of mold standard parts will get better and better;

5) Develop high-quality mold materials and advanced surface treatment technology;

Post time: Apr-12-2022